#Ointment Manufacturing Plant

Explore tagged Tumblr posts

Text

Ointment Cream Production Line

Ointment Cream Production Line (Ointment manufacturing line) including topicals production line is suitable to produce ointments, cream, lotion, gel and toothpaste. Line includes Ointment manufacturing plant, tube filling machine or container filling machine, capping machine, labeling machines. Cream Filling Line is uses in pharmaceutical, cosmetic, chemical and food industry.

0 notes

Text

Top Manufacturing Solutions for Pharma & Cosmetic Industries

In the dynamic world of pharmaceutical and cosmetic manufacturing, quality, efficiency, and precision are paramount. At Pharmachem Cosmetics, we understand the importance of using state-of-the-art equipment to ensure top-tier products. Whether you're producing ointments, oral liquids, or other cosmetic formulations, having the right machinery is crucial for success. In this blog, we'll highlight essential equipment and machinery that every manufacturer in the pharmaceutical and cosmetic industries should consider.

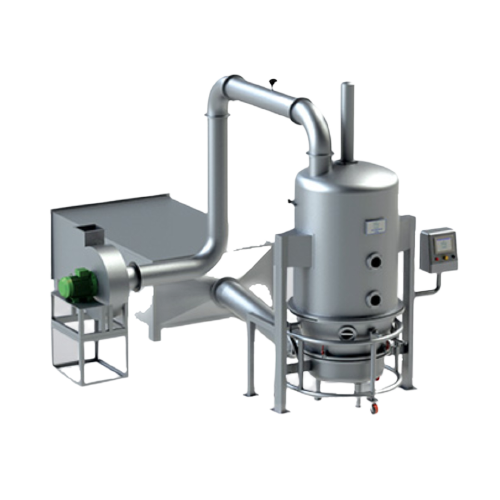

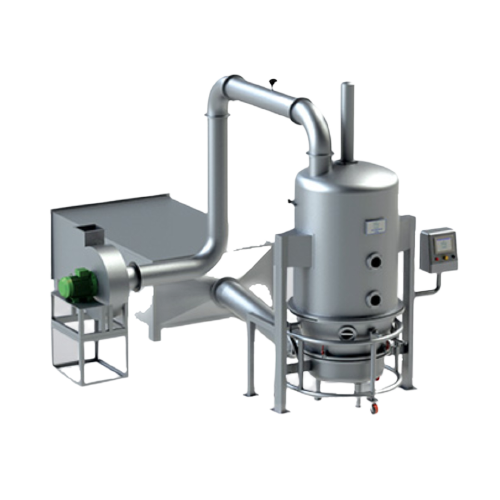

1. Fluid Bed Dryer Manufacturers: Enhancing Product Drying Efficiency

When it comes to drying powders, granules, or other materials in the pharmaceutical and cosmetic industries, Fluid Bed Dryers are indispensable. These dryers operate on the principle of fluidization, where hot air flows through the material, reducing moisture content quickly and efficiently. Fluid Bed Dryer Manufacturers like Pharmachem Cosmetics offer equipment designed for consistency, high-quality results, and energy efficiency, making them ideal for drying sensitive products such as powders, granules, and even some ointments.

Choosing the right Fluid Bed Dryer can significantly impact production timelines and product quality. At Pharmachem Cosmetics, we offer advanced Fluid Bed Dryers that meet industry standards and are customizable for different batch sizes and material types. Our equipment ensures uniform drying, preventing clumping and enhancing the overall product stability.

2. Ribbon Blender Mixer in Maharashtra: Optimal Mixing for Uniform Results

Uniformity in mixing is crucial for the success of any pharmaceutical or cosmetic product. The Ribbon Blender Mixer, a common choice in manufacturing plants, provides an efficient solution for blending powders and granules. This versatile equipment ensures thorough mixing of dry ingredients, resulting in uniform consistency throughout the batch.

Pharmachem Cosmetics, based in Maharashtra, is a leading provider of Ribbon Blender Mixers known for their precision and reliability. Whether you are blending active pharmaceutical ingredients (APIs) or cosmetic powders, our Ribbon Blender Mixers are designed to handle a wide range of formulations with ease. By providing a homogeneous blend, these mixers help in achieving the desired product quality, reducing waste, and optimizing production time.

3. Liquid Oral Manufacturing Plant Suppliers: The Backbone of Liquid Formulations

The demand for liquid oral medications and cosmetic products is on the rise. Whether it’s syrups, tonics, or oral gels, the liquid formulation process requires specialized manufacturing plants equipped with the latest technology. Liquid Oral Manufacturing Plant Suppliers like Pharmachem Cosmetics provide cutting-edge equipment for the smooth production of liquid formulations.

From raw material mixing to bottling and packaging, our liquid oral manufacturing plants are designed to ensure safety, hygiene, and efficiency. With automated systems and robust machinery, we help streamline your liquid production process, reducing contamination risks and ensuring consistent product quality. As a trusted supplier in the industry, Pharmachem Cosmetics ensures that your plant meets regulatory standards and operates at peak performance.

4. Ointment Manufacturing Plant Dealers: Producing High-Quality Ointments

Ointments are among the most widely used formulations in both the pharmaceutical and cosmetic industries. From topical treatments to skincare products, the right manufacturing process is essential to ensure the effectiveness and safety of the ointment. Pharmachem Cosmetics offers high-quality Ointment Manufacturing Plants, designed to produce consistent and reliable ointments for a variety of applications.

Our ointment manufacturing plants are equipped with advanced machinery such as mixers, homogenizers, and filling machines, designed to handle both small and large batches. As leading Ointment Manufacturing Plant Dealers, we provide you with everything you need to produce high-quality ointments while adhering to strict regulatory guidelines.

5. Multi Mill Manufacturers: Versatile and Efficient Milling Solutions

The Multi Mill is one of the most versatile machines used in the pharmaceutical and cosmetic industries. Capable of performing a range of functions such as grinding, milling, shredding, and crushing, the Multi Mill is an essential tool for reducing the size of materials for further processing. Whether you are working with APIs, herbal ingredients, or cosmetic raw materials, the Multi Mill ensures uniform particle size reduction, improving product consistency and performance.

At Pharmachem Cosmetics, we are proud to be recognized as leading Multi Mill Manufacturers, offering equipment that guarantees high throughput, durability, and ease of maintenance. Our Multi Mills are designed with user-friendly controls and are highly adaptable to different production needs.

Conclusion: Quality Equipment for Exceptional Products

At Pharmachem Cosmetics, we are committed to providing the highest quality manufacturing equipment for the pharmaceutical and cosmetic industries. Whether you are in need of Fluid Bed Dryers, Ribbon Blender Mixers, Liquid Oral Manufacturing Plants, Ointment Manufacturing Plants, or Multi Mills, we offer cutting-edge solutions to meet your production requirements.

Partner with Pharmachem Cosmetics today and elevate your manufacturing process to new heights. Our equipment ensures precision, efficiency, and safety in every batch, helping you deliver exceptional products to your customers.

#Multi Mill Manufacturers#Ribbon Blender Mixer in Maharashtra#Fluid Bed Dryer Manufacturers#Liquid Oral Manufacturing Plant Suppliers#Ointment Manufacturing Plant Dealers

1 note

·

View note

Text

Top-Quality Bag Filters from Aryan Engineers – Your Trusted Partner

Aryan Engineers stands as a trusted name in the realm of bag filter manufacturer in India, offering a diverse range of solutions to meet the evolving needs of various industries. With a focus on quality, innovation, and customer satisfaction, we take pride in being a reliable partner for businesses seeking top-notch equipment that enhances their operational efficiency and productivity.

Discover precision-engineered ointment manufacturing vessels at Aryan Engineers, designed to meet stringent quality standards and facilitate the production of pharmaceutical and cosmetic products with accuracy and consistency. Our ointment manufacturing vessels are crafted with attention to detail to ensure optimal performance and reliability in your manufacturing processes.

Reliable liquid manufacturing plant for Consistent Quality

As a leading liquid manufacturing plant, Aryan Engineers specializes in delivering state-of-the-art plants that enable efficient production of liquid products across diverse industries. Our liquid manufacturing plants are engineered to streamline the manufacturing process, ensuring high-quality output while optimizing operational costs and resources.

Experience the superior filtration capabilities with zero hold up filter press manufacturer, designed to efficiently separate solids from liquids with minimal loss and maximum clarity. Our zero hold up filter presses are ideal for applications requiring precise filtration, consistent results, and easy maintenance, making them a valuable asset in various industrial processes.

At Aryan Engineers, customer-centricity is ingrained in our ethos. We are committed to understanding our clients' unique requirements, providing tailored solutions, and offering exceptional service to ensure their complete satisfaction with our products and services.

#bag filter manufacturer in India#ointment manufacturing vessels#liquid manufacturing plant#zero hold up filter press manufacturer

0 notes

Text

[@jynxd]

Satisfaction was all too often earned through pain and frustration. He knew this well after Vander, and even more so after the trouble with the Firelights. He had expected confrontations and scuffles along the way to securing his empire of shimmer within Zaun, but he hadn't expected such a large fly to nestle itself into his ointment. Time after time again, he had faced reports of failed deliveries and disrupted smuggling plans. It was enough to give anyone a headache, even him. Eventually, he was certain, the satisfaction of capturing their troublesome leader would be his.

And he wasn't mistaken. All it would take was some time and escalation.

What he had not expected was their level of resourcefulness. Not only had they discovered one of his shimmer plants, they had found out which days he went to inspect it. He had been flanked by two of his best men as he walked through the manufacturing lines, paying little attention to the underage workers moving and processing his drugs. They were all parts of the grand machine fueling Zaun's soon-to-come independence. Their parents should have been proud, if any of them had parents at all. Then, amongst the crowds of juvenile faces, he spotted a mask.

Before his men could react, they were set upon by at least a dozen of the Firelights, mounted atop their hoverboards and armed with blunt objects like pipes, nail-spiked planks, and dulled blades. While his men set to protecting him, they were easily taken down by crystal bombs, pinning them to the metal grate flooring of the catwalks. Silco, now left to defend himself, reached for his knife and shouted an order to activate the chemtank guards.

It was chaos. Firelights swarmed about him, all of them ready to take their swings. A few hits landed, with one particularly painful strike to his shoulder with a nail-ridden wooden board. He was able to pay that back in kind by slashing the neck of its wielder. As soon as the chemtank guards were activated by a child worker, the fight was his. He watched as they leapt from wall to wall, picking the Firelights down one by one with brutal efficiency.

Out of all of them, only one was left, battered, bruised, and bloodied from the battle. It was time to gather information, then. He gave the signal of a whistle and snap of his fingers, and the programmed obedience of the chemtank guards kicked in. They stopped their attack, hauntingly shifting to a more idle state as he approached the downed firelight. "Well, well. Aren't you a strong one." He knelt down on one knee to peer down at him. His eyes grew wide when he recognized the mask from descriptions. "Ahhh, so you must be the leader of this little group. I have so many questions to ask you." A smile grew on his slim lips.

Satisfaction through pain and frustration.

62 notes

·

View notes

Text

Cottonseed Oil Market Demand in Food and Industrial Sectors

Cottonseed oil is an essential edible and industrial oil extracted from the seeds of cotton plants. It has gained widespread application in the food, pharmaceutical, and cosmetic industries, making it a crucial commodity in the global market. The growing demand for healthier cooking oils, along with expanding industrial uses, has contributed to the steady growth of the cottonseed oil market. This article explores the key factors driving market demand, current trends, and future growth prospects.

Key Drivers of Cottonseed Oil Market Demand

Increasing Use in the Food Industry The primary driver of cottonseed oil demand is its extensive use in the food industry. It is a preferred oil for frying and baking due to its neutral flavor and long shelf life. Fast food chains, snack manufacturers, and bakery producers are key consumers of cottonseed oil, fueling its demand.

Health Benefits and Consumer Awareness With rising health consciousness, consumers are seeking healthier alternatives to traditional cooking oils. Cottonseed oil contains low cholesterol and high levels of unsaturated fats, making it an attractive option for health-conscious consumers. Its balance of omega-3 and omega-6 fatty acids also contributes to cardiovascular health.

Growing Demand in the Cosmetics and Personal Care Industry Cottonseed oil is widely used in skincare and haircare products due to its moisturizing and anti-inflammatory properties. The increasing popularity of natural and organic cosmetics has further fueled demand, as manufacturers prefer plant-based ingredients over synthetic alternatives.

Expanding Use in the Pharmaceutical Industry The pharmaceutical industry utilizes cottonseed oil as a base ingredient in medicines, ointments, and vitamin supplements. With the rising demand for pharmaceutical products globally, the need for high-quality carrier oils like cottonseed oil is increasing.

Industrial Applications and Biofuel Potential Apart from food and pharmaceutical uses, cottonseed oil finds applications in the production of lubricants, paints, and biodiesel. The push for renewable energy sources and sustainable industrial practices has contributed to the increased demand for plant-based oils like cottonseed oil.

Regional Market Trends

North America The United States is one of the largest consumers of cottonseed oil, primarily driven by its extensive use in food processing industries. The trend toward healthier eating habits has further contributed to its demand in cooking applications.

Asia-Pacific Countries like China and India are major producers and consumers of cottonseed oil. The oil is widely used in traditional cooking, making it a staple in many households. Additionally, the growing food processing industry in the region has boosted market demand.

Europe The European market is experiencing steady growth, driven by the increasing demand for plant-based oils in the cosmetics and pharmaceutical sectors. The region's focus on sustainable and organic products has further enhanced market opportunities.

Latin America and Africa Cottonseed oil demand in these regions is growing due to increased agricultural activities and expanding food industries. Government initiatives promoting the use of local oils for domestic consumption have also contributed to market growth.

Challenges Facing the Cottonseed Oil Market

Competition from Alternative Edible Oils The market faces competition from other vegetable oils such as soybean, sunflower, and palm oil, which are often available at lower prices. This creates a challenge for cottonseed oil manufacturers in maintaining market share.

Price Volatility Cottonseed oil prices are influenced by fluctuations in cotton production, global trade policies, and climatic conditions. Price instability can impact demand, especially in price-sensitive markets.

Regulatory Restrictions Stringent regulations on genetically modified (GM) crops affect cottonseed oil production in certain regions. Many countries impose labeling requirements on GM products, influencing consumer preferences and market demand.

Supply Chain Disruptions Global supply chain challenges, including transportation costs and raw material shortages, can impact the availability of cottonseed oil. The COVID-19 pandemic and geopolitical tensions have further highlighted the importance of resilient supply chains.

Future Growth Prospects

Expansion of the Organic Cottonseed Oil Market As demand for organic and non-GMO products increases, manufacturers are focusing on producing organic cottonseed oil. This segment is expected to witness significant growth, particularly in North America and Europe.

Rising Demand for Sustainable and Renewable Oils With increasing awareness of sustainability, industries are shifting toward eco-friendly alternatives. Cottonseed oil, being plant-based and biodegradable, aligns with the global sustainability movement, driving its future demand.

Technological Advancements in Oil Extraction Innovations in extraction techniques, such as cold pressing and refining, are improving the quality and yield of cottonseed oil. These advancements are expected to enhance market competitiveness and open new opportunities for manufacturers.

Emerging Markets and Trade Opportunities Developing economies in Africa and Latin America are showing promising growth in cotton production. Increased trade agreements and investment in oil extraction facilities will likely boost the cottonseed oil market in these regions.

Conclusion

The cottonseed oil market is experiencing steady growth, driven by its diverse applications across the food, pharmaceutical, and industrial sectors. While challenges such as price volatility and competition from alternative oils persist, the rising demand for healthier and sustainable oils presents significant growth opportunities. As technological advancements improve production efficiency and emerging markets contribute to global demand, the future of the cottonseed oil market remains promising.

0 notes

Text

Effects of Two Propagation Methods on Growth and Seed Yield of Jatropha curcas (L.) in Tandjilé Region, Chad

Abstract

Field trial was carried out in Chad to investigate the effects of two plants propagation methods on productivity of Jatropha curcas L. cultivated in four localities (Djoun, Insatal, Laï-Djoum and Tchoua) at Tandjilé region in Chad. Planting was done following a randomized block design with four replications and two treatments (plants propagation methods: cuttings of stem and seedling). Physico-chemical properties of growing soils were assessed. The growing parameters and seeds yield were evaluated. Results shown that growing parameters and seeds yield were significantly different (p˂0.05) between both plants propagation methods and four study localities. J. curcas adapted better in Tchoua locality than other three experimental sites. Cuttings of stem exhibited the highest (104±1.9 Kg/ha) seeds yield while the lowest (88±3.7 Kg/ha) is observed under seedling plants propagation method in each of four study sites. It comes out from this study that plants propagation method using cuttings of stem can be recommended to farmers of Tandjilé region (Chad) to be integrated into their agricultural systems for J. curcas growth.

Introduction

National communities, non-governmental organizations, national and international institutions have in recent years become aware the danger posed by the emission of greenhouse gases, particularly carbon dioxide whose fossil fuel constitutes the main emission source (Minengu et al., 2014). Faced with the industries development and exponential growth of world's population, it is urgent to find a source of alternative energy to avoid energy crisis (Fall, 2007; Sall, 2007). Research focuses on bioenergy, particularly on non-edible plants that can produce oils with biofuel potentiality (Dieye, 2007; Bellefontaine, 2001; Nwaga, 2009). Jatropha curcas L., a shrub belonging to the Euphorbiaceae family, is one of the vegetable species that can solve energy problems because the oil extracted from its seeds can be used as biofuels without competing with food crops. J. Curcas growth well in intercropping with food crop (Dauriat et al., 2001, FAO, 2010). This plant is not edible for humans or livestock. It is widely used in traditional medicine. Seeds oil from J. curcas is used in the manufacture of biofuel, handmade soap, ointment and then used as insecticides and nematocides for crops protection (Hammaoui, 2006).

The cake obtained after seeds oil extraction is an excellent organic fertilizer for crops (Penjit, 2012). This cake can be used as fodder for livestock after detoxification (Kasuya et al., 2013). The stem of J. curcas is used for hedgerows construction. J. curcas adapts to various soils, withstands long periods of drought and requires very little maintenance. But its optimal production requires a well-drained and fertile soil (Bellefontaine, 2001; Olivier, 2007). Many countries in the world, including America, Asia and recently some West African countries have embarked on its culture for biofuels production. The Sudanian zone of Chad offers a favorable climate for planting this shrub in order to solve the socio-economic needs of population stricken by poverty. The purpose of this work was to evaluate (1) the physico-chemical characteristics of soils from Sudanian savannah of Tandjilé (Chad), (2) plants propagation methods (seedling and cuttings of stem) as well as localities of Sudanian savannah of Tandjilé (Chad) on J. curcas growth and development. The importance and usefulness of this work follows from the fact that the plants propagation method and the Chad study area which will provide the highest seeds yield of J. curcas will be popularized.

Source : Effects of Two Propagation Methods on Growth and Seed Yield of Jatropha curcas (L.) in Tandjilé Region, Chad | InformativeBD

1 note

·

View note

Text

Ointment Manufacturing Plant

We are leading manufacturer of Ointment manufacturing plant of world class structure at our state of art unit. We provide excellent modular system with advanced processing technology & reliable quality assurance at each and every step.

Ointment Manufacturing Plant

0 notes

Text

Tannic Acid Manufacturer in Delhi — Akshat Rasayan

Specialty chemicals like tannic acid require manufacturers who prioritize trust, quality, and innovation. As a leading tannic acid manufacturer in Delhi, Akshat Rasayan has earned a reputation for providing premium-grade solutions tailored to diverse industrial needs. With a legacy of excellence in the chemical industry, we are the reliable choice for businesses seeking superior products and exceptional service.

Understanding Tannic Acid

Tannic acid is a naturally occurring compound derived from plant-based tannins. Renowned for its astringent properties and versatility, tannic acid serves various industries, including:

Food and Beverage: Enhances flavors and acts as a clarifying agent.

Pharmaceuticals: Widely used for its wound-healing and antibacterial qualities.

Leather Processing: Crucial in tanning processes for improved durability and finish.

Textiles and Printing: Functions as a mordant in dyeing and ink production.

Alcoholic Beverages: Plays a vital role in improving flavor, color, and clarity.

Akshat Rasayan: Setting the Benchmark for Quality

At Akshat Rasayan, we recognize the significance of tannic acid across various industries and are committed to delivering consistent quality. Our advanced manufacturing techniques, paired with rigorous quality control, ensure that every product meets the highest standards of safety, purity, and effectiveness.

Why Akshat Rasayan is the Preferred Choice for Tannic Acid

1. Unmatched Quality Control Each batch of our tannic acid undergoes strict testing to ensure optimal performance, purity, and compliance with international standards.

2. Multi-Industry Applications From leather tanning to food processing, we supply tannic acid suitable for a broad spectrum of applications, offering versatility and reliability.

3. Affordable Excellence By balancing cost-efficiency and top-tier quality, we provide businesses with high-value solutions that don’t compromise performance.

4. Exceptional Customer Care We support our customers with expert technical assistance, flexible packaging options, and timely deliveries to streamline operations and maximize results.

Applications of Tannic Acid Supplied by Akshat Rasayan

Leather Industry

Our tannic acid enhances the tanning process, improving leather’s durability and creating a superior finish that meets industrial standards.

Food & Beverage Industry

Food-grade tannic acid plays a vital role in beverage clarification and flavor stability, especially in wines and beers.

Pharmaceutical Products

We supply pharmaceutical-grade tannic acid recognized for its antibacterial and astringent properties, used in healing ointments and other medical applications.

Industrial Applications

Tannic acid is an indispensable component in the textile dyeing process, ensuring vibrant, long-lasting colors. Its utility in ink production also makes it a preferred choice for the printing industry.

Sustainability at Akshat Rasayan

At Akshat Rasayan, sustainability is more than just a commitment—it’s an integral part of our mission. Our environmentally friendly production processes aim to minimize waste and reduce our ecological footprint, ensuring a positive impact on the planet while delivering top-notch products.

Partner with Akshat Rasayan Today

Whether your needs lie in pharmaceuticals, food processing, leather tanning, or industrial manufacturing, Akshat Rasayan is the go-to tannic acid supplier in Delhi. With our unwavering dedication to quality, innovation, and customer satisfaction, we empower industries to thrive.

Get in touch with us today to learn more about how our tannic acid can add exceptional value to your business operations.

0 notes

Text

Castor Oil Prices Trend | Pricing | News | Database | Chart

The global castor oil market has experienced significant fluctuations in pricing over the past decade, driven by a combination of supply and demand dynamics, production challenges, and geopolitical factors. Castor oil, extracted from the seeds of the Ricinus communis plant, is renowned for its versatile applications across industries such as pharmaceuticals, cosmetics, automotive, and manufacturing. The market for castor oil is influenced by a multitude of factors including production levels, climate conditions, trade policies, and shifting consumer preferences, all of which contribute to the pricing trends observed in recent years.

One of the most critical aspects affecting castor oil prices is the production capacity of major suppliers. India is the leading producer of castor oil, contributing to nearly 80% of the world’s supply. The country’s production is heavily impacted by agricultural practices, monsoon patterns, and government policies related to crop support. Variations in the annual yield due to unpredictable weather conditions can lead to price volatility. For instance, a deficit in the expected production due to poor monsoon rains or adverse climate conditions can result in a supply shortage, pushing prices higher. Conversely, a surplus crop yields lower prices as market supply exceeds demand.

Get Real time Prices for Castor Oil: https://www.chemanalyst.com/Pricing-data/castor-oil-1537

Trade policies and tariffs also play a pivotal role in shaping the castor oil market. As countries negotiate trade agreements and impose tariffs, these measures directly impact the cost and flow of castor oil. India, being the dominant exporter, has faced fluctuating export tariffs that can either enhance or hinder its competitive edge in global markets. For instance, when export tariffs are lowered or eliminated, it encourages international trade, thereby stabilizing or reducing prices. On the other hand, an increase in tariffs may drive up prices due to limited availability in international markets.

Global demand for castor oil has seen steady growth, driven by the increasing use of castor oil derivatives in various industries. In the pharmaceutical sector, castor oil is valued for its anti-inflammatory and antimicrobial properties, making it a preferred ingredient in certain medicines, lubricants, and ointments. The beauty and personal care industry has also contributed to the increased demand for castor oil, especially with the rising consumer interest in natural and organic products. Castor oil’s unique properties, including its moisturizing and conditioning abilities, have made it a popular component in hair care and skin care products. This growing trend toward natural and plant-based ingredients has fueled demand and subsequently impacted prices.

In the automotive industry, castor oil is utilized in the production of bio-based lubricants and hydraulic fluids. This aspect of the market has seen expansion, particularly with the growing focus on sustainable and eco-friendly solutions. Government regulations and initiatives promoting the use of renewable resources have further bolstered this sector’s growth. As industries continue to seek alternatives to conventional petroleum-based products, the role of castor oil as a renewable and biodegradable option gains importance, influencing its market valuation.

Additionally, innovation and technological advancements are contributing to shifts in the market. New extraction techniques and processing methods have improved the efficiency of castor oil production, potentially impacting costs. While the initial setup for more advanced production methods may be high, over time, they lead to lower per-unit costs and could result in reduced prices for consumers. Furthermore, increased investments in research and development (R&D) are driving the creation of new castor oil-based products that cater to different market needs, which in turn, affects overall pricing trends.

The global castor oil market is also influenced by sustainability and environmental concerns. As consumers and industries place greater emphasis on sustainable practices, there is growing interest in sourcing castor oil from suppliers that adhere to eco-friendly and ethical farming practices. This shift has led to a demand for certified and traceable castor oil, often commanding higher prices. The cost of certification and adherence to stringent environmental standards can add to production costs, ultimately impacting the price at which castor oil is sold. However, this approach aligns with the broader trend of sustainability and eco-conscious consumer behavior, making it a strategic investment for suppliers.

Overall, the castor oil market remains dynamic, subject to varying factors such as production challenges, shifts in consumer demand, geopolitical developments, and advancements in technology. The prices of castor oil reflect this complexity, with periods of stability and sudden price surges. Industry participants, from producers to end-users, must remain agile and informed to navigate these fluctuations effectively. As sustainability becomes a focal point and innovation continues to shape product development, the future of the castor oil market is poised to witness continued evolution, with pricing strategies adjusting to reflect these changes.

Get Real time Prices for Castor Oil: https://www.chemanalyst.com/Pricing-data/castor-oil-1537

Contact Us:

ChemAnalyst

GmbH - S-01, 2.floor, Subbelrather Straße,

15a Cologne, 50823, Germany

Call: +49-221-6505-8833

Email: [email protected]

Website: https://www.chemanalyst.com

#Castor Oil#Castor Oil Prices#Castor Oil Pricing#Castor Oil Demand#Castor Oil Supply#Castor Oil News

0 notes

Text

Nicotine Sulphate: A Key Component in Pharma Products and Active Pharmaceutical Ingredients

Introduction

In the ever-evolving world of pharmaceuticals, certain compounds stand out for their versatility and unique applications. One such compound is nicotine sulphate, a chemical derived from nicotine and sulfuric acid. While nicotine sulphate is best known for its historical use in insecticides, its applications in the pharmaceutical industry have garnered increasing attention. As an essential component in certain pharma products, nicotine sulphate plays a crucial role in the production of specific active pharmaceutical ingredients (APIs). In this article, we will explore the diverse nicotine sulphate uses, its role in APIs pharma, its significance in the Indian market for active pharmaceutical ingredients, and the contributions of companies like Prism Industries, known for their exceptional commitment to delivering quality pharmaceutical ingredients.

What is Nicotine Sulphate?

Nicotine sulphate is a chemical compound formed by reacting nicotine, an alkaloid primarily derived from the tobacco plant, with sulfuric acid. It appears as a dark brown or black liquid with a strong, pungent odor. Historically, nicotine sulphate was widely used as an insecticide due to the toxic properties of nicotine. However, its applications extend beyond the agricultural industry. In pharmaceuticals, nicotine sulphate serves as a key active pharmaceutical ingredient (API) in specific formulations.

Despite the decline of nicotine sulphate in the pesticide industry, its role in the production of APIs for pharmaceutical products cannot be overlooked. It is used in the synthesis of several medications and formulations, particularly in combination with other agents, to treat various conditions.

Nicotine Sulphate Uses: Diverse Applications

While nicotine sulphate is most famous for its historical role in pest control, its pharmaceutical applications are also significant. Below are some of the primary uses of nicotine sulphate in the pharmaceutical industry:

1. Smoking Cessation Products

One of the most recognized nicotine sulphate uses is in smoking cessation therapies. Nicotine sulphate serves as a source of nicotine in various pharmaceutical forms aimed at helping individuals quit smoking. Nicotine replacement therapy (NRT) includes products such as patches, gum, and lozenges that deliver controlled doses of nicotine to reduce withdrawal symptoms and cravings. Though nicotine is primarily used in the form of nicotine gum or patches, nicotine sulphate can be converted into other nicotine-based formulations in smoking cessation products.

2. Topical Formulations

Nicotine sulphate is used in certain topical products that treat various conditions. For example, nicotine sulphate is sometimes included in ointments designed to promote blood circulation. The compound’s ability to stimulate blood flow and act as a vasodilator has found use in some pharmaceutical preparations for topical application, often in conjunction with other therapeutic agents to improve effectiveness.

3. Antiseptic and Antibacterial Treatments

Another potential nicotine sulphate use is in antiseptic formulations, where the compound acts as a mild antibacterial agent. The toxic properties of nicotine, when appropriately diluted and processed, can help create formulations that target specific pathogens. Although nicotine sulphate’s role in this application is limited, it contributes to certain pharma products that require specialized antimicrobial properties.

4. Insecticide and Pest Control in Pharmacies

Interestingly, the nicotine sulphate uses extend beyond pharmaceuticals into pharmacy-related pest control products. Nicotine sulphate has a reputation as an effective insecticide, especially in managing pests in pharmaceutical manufacturing environments. Its insecticidal properties ensure that contamination does not affect the quality of pharmaceutical products. While it is no longer widely used in consumer pesticide products, its role in maintaining pest-free environments within pharmaceutical facilities remains valuable.

Active Pharmaceutical Ingredients (APIs) in Pharma Products

In the world of pharmaceutical manufacturing, active pharmaceutical ingredients (APIs) are the essential elements that give a drug its therapeutic effect. Nicotine sulphate is one of the many specialized APIs pharma companies utilize to formulate medicines for various diseases and conditions. The importance of nicotine sulphate as an API can be attributed to its unique characteristics and potential to serve in niche pharmaceutical applications.

1. The Role of Nicotine Sulphate in Pharma Products

The production of pharma products often requires specialized chemicals to provide desired effects in patients. Nicotine sulphate serves as a vital API in some pharmaceutical products due to its pharmacological properties. In smoking cessation aids, for example, nicotine sulphate offers a source of nicotine that helps mimic the physiological effects of smoking. It is carefully formulated to provide controlled dosages that reduce withdrawal symptoms in patients trying to quit.

2. Manufacturing of Active Pharmaceutical Ingredients in India

India is a leading hub for the production and export of active pharmaceutical ingredients. As a prominent player in the global APIs pharma sector, India produces a vast array of ingredients, including nicotine sulphate for its niche applications. Pharmaceutical companies across India specialize in the synthesis, purification, and distribution of APIs, ensuring that quality products meet global pharmaceutical standards.

Active pharmaceutical ingredients in India are regulated by authorities such as the Central Drugs Standard Control Organization (CDSCO) and international organizations like the World Health Organization (WHO). Companies such as Prism Industries, which is known for producing high-quality active pharmaceutical ingredients, are instrumental in ensuring that nicotine sulphate and other compounds meet rigorous standards of safety and efficacy.

Active Pharmaceutical Ingredients for Prism Industries: A Commitment to Quality

Prism Industries, a trusted name in the pharmaceutical manufacturing world, has made significant contributions to the industry by producing premium active pharmaceutical ingredients. The company’s dedication to excellence has allowed it to develop a robust portfolio of APIs, including those that incorporate nicotine sulphate in specific treatments.

1. Prism Industries’ Commitment to Quality

Prism Industries takes pride in its stringent quality control processes, which ensure that every API it produces meets both domestic and international standards. Whether it’s nicotine sulphate or other critical APIs, Prism Industries ensures that the highest levels of purity and quality are maintained throughout the manufacturing process. The company adheres to Good Manufacturing Practices (GMP) to guarantee that every batch of nicotine sulphate is produced with precision and care.

2. Manufacturing and Distribution Capabilities

Prism Industries boasts state-of-the-art manufacturing facilities designed to handle the production of specialized active pharmaceutical ingredients like nicotine sulphate. These facilities are equipped with advanced equipment and undergo regular audits to ensure compliance with global standards. By leveraging cutting-edge technology, Prism Industries is able to maintain a competitive edge in the pharmaceutical market, providing high-quality APIs to pharmaceutical companies worldwide.

3. Unique Positioning of Prism Industries

What sets Prism Industries apart in the competitive pharmaceutical landscape is its ability to focus on both high-volume APIs and niche products like nicotine sulphate. This enables the company to cater to diverse pharmaceutical needs, from large-scale production of common APIs to the development of more specialized compounds. This uniqueness allows Prism Industries to serve both local and international markets with a wide range of products.

Conclusion

Nicotine sulphate, while historically associated with insecticides, has emerged as a valuable component in pharma products and active pharmaceutical ingredients. From its role in smoking cessation products to its use in specific topical formulations, nicotine sulphate uses are diverse and vital to the pharmaceutical industry. As part of the broader world of APIs pharma, nicotine sulphate plays an essential role in developing medications that help people lead healthier lives.

Companies like Prism Industries are crucial in maintaining the quality and safety of active pharmaceutical ingredients, including nicotine sulphate. By adhering to stringent quality standards and leveraging cutting-edge manufacturing technologies, Prism Industries continues to provide reliable APIs that meet the diverse needs of the global pharmaceutical market.

In conclusion, the evolving role of nicotine sulphate in pharmaceutical products highlights the importance of specialized compounds in the ongoing development of medicines. With continued innovation and dedication to quality, nicotine sulphate will remain an important active pharmaceutical ingredient in treating specific health conditions while helping companies like Prism Industries lead the way in the APIs pharma sector.

#nicotine_sulphate#nicotine_sulphate_uses#pharma_products#apis_pharma#active_pharma_ingredients_india

0 notes

Text

Ointment/Cream Manufacturing Plant

youtube

Ointment Manufacturing Plant is an ideal tool for the pharmaceutical & cosmetic industries for the production of Ointment, Cream, Lotions, Tooth Paste & other emulsions & homogenizations. It is specially designed to take care of two critical factors which directly affects the quality of the Ointment/Creams.

Minimum man handling of Ointment.

Negligible vacuum drop during mixing & blending.

Needless to say, it also provides the benefits of the effective manpower utilization.

0 notes

Text

Menthol Oil Suppliers in India: What Makes Them Stand Out?

Menthol oil is famous for its cooling and therapeutic properties, on which its use has become vital in almost every industry—from pharmaceuticals to formulations for cosmetic use, wellness products, and so on. India is one of the nations producing and exporting essential oils. Menthol oil suppliers in India are primarily trusted names in menthol for their quality and consistency. This post is centered around what makes these suppliers unique and their industry roles in contributing to different markets as well as meeting global demands.

All About Menthol Oil and Its Uses

Menthol oil is obtained from peppermint or other mint species and is rich in menthol, the chemical compound responsible for cooling sensations. Menthol oil has a few uses, and among these are:

Respiratory Relief: Relief from nasal catarrh, coughs, and cold symptoms. Menthol oil is a searing ingredient in balms, inhalers, and vapor rubs.

Pain Management: The cooling effects of menthol oil enable helping to reduce muscle pain and headaches. Office use of topical ointments enables quick escape from the ill effects.

Skin Care: Valued for its anti-inflammatory and soothing effect, menthol oil is prized among skin creams and lotions for irritated skin.

Aromatherapy: Its refreshing scent is known to reduce stress, induce good focus, and bring about relaxation.

Industrial: Menthol oil is an important component in flavoring, perfumery, and even some cleaning agents' formulations.

Demand for menthol oil has grown enormously, and hence menthol oil suppliers in India are really playing an important role at the global level.

Why India is a Leading Supplier of Menthol Oil

India is one of the largest producers and exporters of menthol oil, primarily because the climatic conditions of the country, combined with agricultural know-how and a very strong industrial setup, contribute to the dominance of the country in essential oil markets. Here’s what sets Menthol Oil Suppliers in India apart:

Access to High-Quality Raw Materials Based on northern regions of India, like Uttar Pradesh, mint cultivation is favorable for growing mint plants. The availability of superior peppermint and spearmint facilitates suppliers in the formulation of superior-grade menthol oil. The quality of raw materials affects the purity and efficacy of the end product directly.

Modern Extraction Techniques The suppliers in India deploy modern extraction techniques to ensure maximum output and purity of menthol oil. Most common methods are steam distillation, which also keeps the natural properties of menthol without compromising on quality.

Commitment to Standards The suppliers of good reputation in India by the haul comply with international standards of quality, including Good Manufacturing Practice (GMP) and ISO certifications. Therefore, it will make the menthol oil meet stringent requirements from the global markets that act favorably for international buyers.

Cost-effective Solutions It is known that Indian suppliers especially provide high-quality menthol oil at competitive prices. This cost advantage with better quality has made Indian menthol oil the first choice for companies all over the world.

Four Features that Define a Good Menthol Oil Supplier in India

The credibility of the source is one of the major factors determining menthol oil quality. Following are some characteristics that differentiate the best menthol oil supplier in India:

Transparency in Sourcing Quality being made available to farmers ensures high-quality mint crops, as the best suppliers believe in grain sourcing by ensuring proper traceability of their raw materials.

Wide Range of Products Most suppliers, apart from menthol oil stock-related products like menthol crystals and various mint-based oils, enable businesses to procure different products from one supplier.

Stringent Quality Checks Renowned suppliers carry on rigorous testing at varied stages involved in the manufacture of menthol oil to keep it in the purest and most potent form. These tests normally include tests for contaminants to make sure the oil is clear of them to make it suitable for use in sensitive applications such as pharmaceuticals and cosmetics.

Environmental Reality Sustainability is becoming the most important factor within the essential oil market. Forward Indian suppliers are adopting green farming and green production processes, thus minimizing damage to the environment while ensuring quality in the end product.

Timeliness A timely delivery is the name of a good competition market. Indian suppliers excel in logistics and supply chain management, so delivery to the clients can never be delayed.

Challenges Faced by Indian Suppliers of Menthol Oil

Indian suppliers of menthol oil face certain challenges despite the numerous strengths:

Weather Dependency: Mint itself is very dependent on weather, and any disruptions—such as droughts or floods—can affect production volumes.

Market Rivalry: In a country such as India, the essential oil industry is very competitive; therefore, all suppliers are competing for a share in a market that demands constant innovation and quality improvement.

Regulatory Compliance: Meeting regulatory requirements for compliance at both domestic and international levels is sometimes difficult and time-consuming for suppliers, which involves investing heavily in compliance measures.

However, menthol oil suppliers in India have remained high performers owing to their resilience and commitment to excellence.

Roles Played by Menthol Oil in Various Industries

Pharmaceutical Industry

Menthol oil is an essential ingredient in the pharmaceutical sector as it boasts therapeutic properties that are used in products like pain balms, cough syrups, and antiseptics.

Cosmetics and Personal Care

Menthol oil is present in many cosmetics, such as cooling creams and refreshing lotions. It is a great ingredient for formulating sensitive skin products because of its soothing effects and anti-inflammatory properties.

Food and Beverage

Menthol oil has many applications, from being a flavoring agent used in the preparation of confectionery, chewing gums, and beverages. It gives a special effect with a cooling sensation in these products.

Aromatherapy

In the wellness industry, menthol oil is the most used essential oil for aromatherapy. Its ability to calm the mind and energize the senses makes it a favorite among therapists and clients alike.

Future Prospects of Menthol Oil Suppliers in India

Demand for menthol oil is expected to rise in the near future, driven by natural and organic product awareness among the general public, and Indian suppliers can take full advantage of this due to their expertise, infrastructure, and commitment.

Moreover, with the growing concern for sustainability, it is apparent that suppliers who opt for eco-friendly practices will certainly gain a competitive share of the market. Moreover, innovations in extraction as well as further processing could increase the efficiency and quality of menthol oil.

Conclusion

The strength of menthol oil suppliers in India lies in their being able to deliver products of high quality that meet the demands of all kinds of industries across countries. Such commitment to quality, innovation, and sustainability is enough to place India in the global league of menthol oil producers.

Trust and assurance are the benchmarks for sourcing menthol oil. Neeraj Chemicals is one proven example of the kind of dedication and expertise required to make a mark in this competitive industry. They are continuing the process of enhancing support to business houses and individuals so that people can recognize the incredible advantages of menthol oil, focusing on quality and customer satisfaction.

1 note

·

View note

Text

Aryan Engineers - Providing Reliable Clean Room Equipment and Filtration Solutions

In the world of pharmaceuticals and healthcare, precision, cleanliness, and efficiency are paramount. When it comes to liquid manufacturing plants, ointment manufacturing plants, and clean room equipment, Aryan Engineers is the name that stands out. As leading experts in the industry, we take pride in delivering top-quality solutions that meet the unique requirements of our clients.

Liquid Manufacturing Plant: Unleashing Precision and Efficiency

At Aryan Engineers, we understand the critical importance of precision in liquid manufacturing. Our liquid manufacturing plants are designed and built with state-of-the-art technology and industry expertise. We employ cutting-edge machinery and automation systems to ensure accurate and consistent production. Whether you require a small-scale or large-scale liquid manufacturing plant, we have the expertise to deliver tailored solutions that meet your specific needs.

Clean Room Equipment Manufacturers: Maintaining Sterility and Compliance

Clean room environments are essential for pharmaceutical and healthcare industries to maintain product integrity and ensure regulatory compliance. As clean room equipment manufacturers, we specialize in designing and supplying a wide range of equipment, including air handling units, laminar airflow units, pass boxes, and much more. Our clean room equipment is built to the highest standards of quality, ensuring optimal cleanliness, particle control, and air filtration. Trust Aryan Engineers to provide you with reliable and efficient clean room solutions.

Ointment Manufacturing Plant: Consistency and Quality Guaranteed

Aryan Engineers excels in designing and constructing ointment manufacturing plants that meet the stringent requirements of the pharmaceutical industry. Our plants are equipped with advanced mixing and blending systems, efficient heating and cooling mechanisms, and precise filling and packaging equipment. We understand the importance of maintaining product consistency and quality throughout the manufacturing process, and our ointment manufacturing plants are built to deliver exactly that.

Bag Filter Manufacturer: Enhancing Process Efficiency and Safety

As a bag filter manufacturer, we offer a comprehensive range of filtration solutions for various industries. Our bag filters are designed to effectively remove contaminants, dust, and particles from air and gas streams, ensuring cleaner and safer working environments. With Aryan Engineers' bag filters, you can enhance process efficiency, reduce maintenance costs, and protect sensitive equipment from harmful particulate matter.

Choose Aryan Engineers for Your Manufacturing Needs

At Aryan Engineers, we are committed to providing our clients with the highest level of customer satisfaction. Our team of experienced engineers and technicians work closely with you to understand your requirements, develop customized solutions, and ensure smooth project execution. We prioritize quality, reliability, and timely delivery, making us the preferred choice for liquid and ointment manufacturing plants, clean room equipment, and bag filters.

Contact Aryan Engineers today to experience seamless manufacturing processes, improved product quality, and enhanced operational efficiency. Trust us to be your partner in success.

#liquid manufacturing plants#clean room equipment manufacturers#ointment manufacturing plants#bag filter manufacturers#Aryan Engineers

0 notes

Text

Zinc Oxide Manufacturers In India

Zinc oxide is a versatile chemical compound used across various industries due to its unique properties and wide-ranging applications. As one of the leading zinc oxide manufacturers in India, Lifesaver Inc. Group is committed to providing high-quality, reliable, and innovative solutions to meet the demands of different sectors, including rubber, pharmaceuticals, cosmetics, agriculture, and more.

What is Zinc Oxide?

Zinc oxide (ZnO) is an inorganic compound that appears as a white, powdery substance and is primarily used for its chemical, physical, and mechanical properties. It is an essential raw material in many industrial processes and products. Zinc oxide is commonly used in the manufacture of tires, paints, sunscreen, ointments, and other specialized products due to its wide range of functions, such as its ability to provide UV protection, act as a catalyst, and enhance the durability of products.

Applications of Zinc Oxide

1. Pharmaceutical and Cosmetic Industry

In the pharmaceutical and cosmetic industries, zinc oxide is a popular ingredient. It is widely used in sunscreens, lotions, creams, and ointments for its ability to protect the skin from harmful ultraviolet (UV) rays. Zinc oxide also has anti-inflammatory properties, which make it an effective treatment for skin irritations, acne, and diaper rash. In addition, it is used in the formulation of various medicinal products, including antiseptic ointments and wound healing creams.

2. Rubber Industry

One of the most significant applications of zinc oxide is in the rubber industry. It is a key ingredient in the production of rubber products, such as tires, footwear, and industrial rubber goods. Zinc oxide acts as an activator in the vulcanization process, improving the strength, elasticity, and durability of rubber. It also plays a critical role in enhancing the heat resistance and wear properties of rubber products.

3. Agriculture

In agriculture, zinc oxide is used as a micronutrient in fertilizers. Zinc is an essential element for plant growth, and its deficiency can lead to stunted growth and poor crop yields. By adding zinc oxide to fertilizers, it ensures that plants have adequate access to this crucial nutrient, promoting healthy crops and higher agricultural productivity.

4. Paints, Coatings, and Adhesives

Zinc oxide is used extensively in the production of paints, coatings, and adhesives. It serves as a white pigment and offers excellent opacity and durability. Additionally, its anti-corrosive properties make it ideal for use in protective coatings and paints. Zinc oxide is also used as a catalyst in various chemical reactions during the manufacturing of industrial adhesives and sealants.

5. Other Industrial Uses

Beyond these key industries, zinc oxide is also used in various other industrial applications, such as the manufacture of electrical components, ceramics, and glass. Its semiconductor properties make it an important material in the electronics industry, where it is used in the production of varistors, diodes, and other electronic components.

Lifesaver Inc. Group’s Commitment to Quality

At Lifesaver Inc. Group, we are dedicated to delivering the highest quality zinc oxide products to our customers. We employ advanced manufacturing techniques, including the use of cutting-edge technology and environmentally friendly processes, to ensure that our products meet the highest standards of purity and performance.

We offer a range of zinc oxide grades to suit the needs of different industries:

Pharmaceutical Grade Zinc Oxide: Safe and effective for use in medicinal products, ointments, and sunscreens.

Rubber Grade Zinc Oxide: Specifically designed for use in the rubber industry to improve durability and performance.

Cosmetic Grade Zinc Oxide: Ideal for skincare products, providing UV protection and anti-inflammatory benefits.

Industrial Grade Zinc Oxide: Used in the production of paints, coatings, and adhesives for enhanced durability and corrosion resistance.

Each batch of zinc oxide we produce undergoes rigorous quality control checks to ensure it meets international standards, ensuring that our customers receive products that are both safe and effective.

Why Choose Lifesaver Inc. Group?

As one of India’s leading zinc oxide manufacturers, we understand the importance of providing reliable, cost-effective solutions for a diverse range of industries. Here’s why you should choose Lifesaver Inc. Group for your zinc oxide needs:

High-Quality Products: Our zinc oxide is manufactured using the latest technology and stringent quality control measures to ensure consistency and purity.

Wide Range of Applications: We provide zinc oxide in various grades to suit the needs of the pharmaceutical, rubber, agricultural, and industrial sectors.

Custom Solutions: We understand that each industry has specific needs, and we offer tailored solutions to meet those demands.

Sustainability: We prioritize eco-friendly practices in our manufacturing process, ensuring minimal environmental impact.

Timely Delivery: We ensure on-time delivery to our customers, with efficient logistics and reliable support.

Conclusion

Lifesaver Inc. Group is committed to providing top-quality zinc oxide products for industries across India and globally. Whether you're in the pharmaceutical, rubber, agriculture, or paint industry, we provide the best zinc oxide solutions to meet your specific needs. By choosing us, you are choosing a partner dedicated to innovation, quality, and customer satisfaction.

To learn more about our range of zinc oxide products and how they can benefit your business, visit Lifesaver Inc. Group today.

#ZincOxideManufacturers #LifesaverIncGroup #RubberIndustry #CosmeticGradeZincOxide #PharmaceuticalZincOxide #IndustrialZincOxide #PaintAndCoatings #AgriculturalZincOxide #QualityManufacturersIndia

0 notes

Text

The Crucial Role of Methyl Salicylate in the Essential Oil Industry: Key Insights for Rosemary Oil Suppliers

The natural health sector is currently experiencing a significant surge in demand for plant-based solutions, as consumers increasingly seek effective and environmentally sustainable products. Among the numerous naturally occurring compounds in essential oils, Birch oil stands out due to its powerful pain-relieving, anti-inflammatory, and therapeutic properties. Derived primarily from wintergreen and sweet birch, Oil of wintergreen plays a critical role in a wide variety of products, including topical pain relief creams, skincare treatments, and other health-related applications. This article explores the importance of Sweet birch oil within the essential oil market, its health benefits, extraction methods, and how companies like Rosemary Oil Suppliers are navigating sustainability challenges while meeting the growing demand.

Understanding Methyl Salicylate

Birch oil is a naturally occurring organic ester found in plants such as wintergreen, sweet birch, and certain pine varieties. It is also commonly known as wintergreen oil, a key ingredient in many personal care products due to its distinctive aroma and numerous health benefits. Known for its analgesic (pain-relieving) and anti-inflammatory properties, Sweet birch oil is an essential component in various topical treatments aimed at soothing muscle pain, easing joint inflammation, and addressing skin irritations.

Structurally, Birch oil closely resembles aspirin, being a methyl ester of salicylic acid. This similarity helps explain its strong anti-inflammatory effects, making it a popular ingredient in ointments, creams, and balms designed to alleviate discomfort from conditions such as arthritis, sore muscles, and stiffness.

Beyond its pain-relieving qualities, Gaultheria oil also possesses mild antimicrobial and antifungal properties. These benefits enhance its usefulness in skincare products, where it helps prevent bacterial growth and supports the treatment of minor infections. This broad spectrum of applications further solidifies its position in the essential oil industry, offering versatility across various wellness and cosmetic products.

Extraction Techniques for Methyl Salicylate

To harness the potent properties of Birch oil, it must be carefully extracted from plant sources. Two primary methods are employed in the essential oil industry: steam distillation and solvent extraction.

Steam Distillation

Steam distillation is the most common method used to extract essential oils, including Methyl Salicylate. During this process, steam passes through the plant material (such as wintergreen leaves or birch bark), causing the essential oils to evaporate. The vapor is then condensed back into liquid form, separating the oil from the water. Steam distillation is favored for its ability to produce pure oils without the need for harsh chemicals, helping preserve the integrity of the extracted Salicylate.

This method is highly regarded for its efficiency and minimal environmental impact. However, it is essential for manufacturers, including Rosemary Oil Suppliers, to regulate temperature and pressure carefully to avoid the loss of volatile compounds, which requires expert oversight throughout the distillation process.

Solvent Extraction

While less commonly used for Methyl Salicylate, solvent extraction may be employed when higher concentrations of the compound are required. In this method, solvents such as ethanol or hexane are used to dissolve the essential oils from the plant material. After the solvent evaporates, the remaining oil undergoes purification to remove any residual chemicals. Although this method results in more concentrated oils, it also necessitates additional purification to ensure that the final product is free from harmful solvent traces.

Both extraction methods demand meticulous care to preserve the purity of Betula oil. Manufacturers, including Rosemary Oil Suppliers, must adhere to strict quality control standards during these processes to ensure the final product is both safe and effective.

Therapeutic Benefits of Methyl Salicylate

One of the primary reasons Birch oil is so highly valued in the essential oil industry is its wide range of therapeutic benefits. Most notably, Oil of wintergreen is renowned for its potent pain-relieving and anti-inflammatory properties, making it a sought-after ingredient in topical pain relief products.

Pain Relief and Inflammation Reduction

The pain-relieving properties of Sweet birch oil stem from its counterirritant effect. When applied to the skin, Methyl Salicylate induces a warming or cooling sensation that stimulates blood flow to the affected area, which helps to reduce pain and inflammation. This mechanism makes Wintergreen extract highly effective for treating muscle strains, joint pain, arthritis, and general stiffness.

The soothing sensation provided by Betula oil serves as a distraction from deeper pain, offering immediate relief for conditions involving sore muscles, joint discomfort, or even headaches. It is commonly found in creams, gels, patches, and balms formulated to target specific areas of pain.

Antimicrobial and Antifungal Effects

In addition to alleviating pain and inflammation, Oil of wintergreen also has mild antimicrobial and antifungal properties, which make it useful in a variety of skincare applications. Studies show that Methyl Salicylate can help slow or prevent the growth of bacteria and fungi, which is beneficial for treating minor skin infections and reducing the risk of conditions like eczema or athlete’s foot.

Because of these properties, Birch oil is commonly incorporated into skincare products like creams, lotions, and ointments. Additionally, it appears in oral care products like toothpaste and mouthwashes, where it helps maintain oral hygiene and freshen breath while providing a mild antiseptic effect.

Muscle Relaxation and Flexibility

Methyl Salicylate is also widely used for its ability to promote muscle relaxation and improve flexibility. When applied to the skin, the compound enhances blood circulation, helping relieve muscle tension and increase range of motion. This is particularly beneficial for athletes, individuals with chronic muscle pain, and those recovering from injuries. The warming or cooling effect of Gaultheria oil also contributes to overall muscle relaxation, making it a go-to ingredient in sports creams, muscle rubs, and other therapeutic products designed to improve mobility and reduce discomfort.

The Vital Role of Rosemary Oil Suppliers

While Betula oil is a crucial component in many essential oils, Rosemary Oil play a vital role in providing another essential ingredient in the industry—rosemary oil. Rosemary essential oil is known for its stimulating aroma and therapeutic qualities, including its ability to enhance mental clarity and relieve pain.

Rosemary Oil provide high-quality rosemary oil, which is often used in combination with Gaultheria oil to enhance circulation and reduce muscle pain. Both rosemary oil and Methyl Salicylate share similar anti-inflammatory and analgesic properties, making them highly effective when combined in formulations targeting pain relief. Furthermore, rosemary oil is extracted using similar methods as wintergreen oil, most commonly through steam distillation, which ensures the oil retains its natural purity and potency.

As consumer demand for natural health products continues to rise, Rosemary Oil are increasingly focused on sourcing oils sustainably. These suppliers ensure that plants are harvested responsibly and that the oils retain their maximum therapeutic properties. Through partnerships with growers and manufacturers, Rosemary Oil Suppliers help ensure their products meet the growing demand for safe, effective, and environmentally friendly oils.

Sustainability Challenges and Future Outlook for Methyl Salicylate

As the demand for Salicylate increases, sustainability has become a significant concern for the essential oil industry. The primary sources of Salicylate ester, including wintergreen and birch trees, are under pressure due to overharvesting and habitat destruction. This has raised concerns about the long-term availability of these plant materials.

To address these challenges, Rosemary Oil Suppliers and other essential oil producers are investing in sustainable practices, including controlled harvesting, replanting efforts, and environmentally responsible distillation methods. Additionally, manufacturers are exploring alternatives to natural sources of Betula oil, such as synthetic production or using other plants with similar chemical compositions, to reduce the strain on natural resources.

The future of Methyl Salicylate in the essential oil market looks promising, with ongoing research revealing new therapeutic applications and benefits. As more consumers turn to natural products, the demand for Gaultheria oil is expected to continue growing, emphasizing the importance of sustainability and responsible sourcing for both Rosemary Oil and other essential oil manufacturers.

Conclusion

Wintergreen oil plays a pivotal role in the essential oil industry due to its proven benefits in pain relief, inflammation reduction, and skincare. Its versatility makes it a key ingredient in various health and wellness products. As consumers increasingly seek natural alternatives, the demand for Methyl Salicylate-based oils will continue to rise.

Rosemary Oil Suppliers play a crucial role in sourcing and distributing high-quality essential oils, including rosemary oil, which complements the effects of Salicylic acid methyl ester in pain relief products. By focusing on sustainable practices, innovation, and quality, these suppliers help ensure the essential oil market can meet the growing demand for safe, effective, and environmentally conscious products.

As the industry continues to evolve, Oil of wintergreen will undoubtedly remain an essential ingredient in natural health solutions, offering a wide range of benefits for pain management, skincare, and overall wellness.

0 notes

Text

Industrial Manufacturing Machines for Efficient Production

In the ever-evolving landscape of industrial manufacturing, efficiency and precision are more critical than ever. Whether in pharmaceuticals, cosmetics, or food production, advanced machinery plays a pivotal role in maintaining high-quality standards while boosting productivity. This article provides an in-depth overview of essential manufacturing machines.

Fluid Bed Dryer The Fluid Bed Dryer is designed for efficient and uniform drying of powders, granules, and other particulate materials. It works by suspending the particles in a stream of heated air, ensuring quick and even drying throughout. This technology is widely used in the pharmaceutical, food, and chemical industries for high-quality results. With temperature and humidity controls, the dryer optimizes the drying process while conserving energy. Its easy-to-clean design and robust construction make it suitable for large-scale manufacturing environments.

Fluid Bed Processor The Fluid Bed Processor is a versatile piece of equipment that can handle drying, granulating, and coating applications in a single unit. It provides exceptional fluidization of particles, resulting in efficient and consistent processing. With adjustable air flow and precise temperature control, it ensures that products are treated uniformly, maximizing efficiency. Ideal for pharmaceutical and food manufacturing, it reduces the time needed for multiple processing steps. Built to meet stringent industry standards, it ensures reliability and easy maintenance for high-volume operations.

Ointment Manufacturing Plant The Ointment Manufacturing Plant is an all-in-one solution for producing high-quality ointments and creams. It includes mixing, homogenizing, emulsifying, and cooling equipment, ensuring a seamless manufacturing process. With precision controls, it provides consistent texture and stability of the final product, essential for pharmaceutical and cosmetic formulations. Designed with stainless-steel components, the plant ensures compliance with hygiene and safety regulations. Its efficient workflow minimizes production time while maintaining the highest standards of quality.

Liquid Filling Machine The Liquid Filling Machine is engineered to handle a wide range of liquid products, from thin solutions to thick viscous substances. It features advanced volumetric filling technology, delivering accurate and consistent fills for each container. Ideal for food, pharmaceutical, and chemical industries, it boosts productivity with high-speed operation. The machine is easy to set up and adjust, making it versatile for various container sizes and shapes. Built with durable materials, it ensures long-term reliability and smooth performance even in demanding environments.

V Blenders V Blenders are specially designed for mixing dry powders and granules evenly, making them ideal for the pharmaceutical and food industries. Their V-shaped design ensures efficient blending by creating a tumbling action, achieving uniform results with minimal energy consumption. These machines are built to handle both small and large batches, offering flexibility in production. With easy-to-clean and corrosion-resistant materials, they maintain a high level of hygiene. V Blenders also come with safety features and robust construction, making them reliable for continuous use in industrial settings.

ROPP Capping Machine The ROPP (Roll-On Pilfer Proof) Capping Machine is designed for the secure sealing of bottles, particularly in the beverage, pharmaceutical, and cosmetic industries. It provides a tamper-evident seal that ensures product integrity and prevents leaks during storage or transport. Equipped with advanced capping technology, it offers precise torque control to avoid damaging the container or cap. The machine can handle a variety of cap sizes and materials, making it highly versatile for different production requirements. Its robust construction and easy-to-use interface make it ideal for high-speed, large-scale manufacturing operations.

Shampoo Manufacturing Plant The Shampoo Manufacturing Plant is a comprehensive system for producing high-quality shampoos and hair care products. It includes pre-mixing, homogenizing, and cooling units to ensure a smooth and consistent product texture. Designed to minimize contamination, the plant features closed-loop systems and stainless-steel construction, meeting strict hygiene standards. The automated controls enable precise ingredient mixing and temperature adjustments, ensuring product uniformity. With energy-efficient processes and easy maintenance, the plant is perfect for large-scale shampoo production while ensuring consistent quality and reduced operational costs.

V-Type Blender The V-Type Blender is engineered for the efficient mixing of dry powders and granules, commonly used in the pharmaceutical, food, and chemical industries. The V-shaped chamber ensures optimal blending by allowing the materials to tumble and mix evenly without the risk of particle degradation. It is suitable for both small and large batch processing, providing flexibility to meet various production demands. Easy to load and discharge, the blender also features a polished interior to reduce residue and make cleaning a breeze. Its sturdy and durable design ensures long-lasting performance and consistent results.

Ghee Filling Machine The Ghee Filling Machine is built to handle the thick and viscous nature of ghee, ensuring precise and consistent filling for containers of various sizes. It is equipped with a servo-driven filling system, providing exceptional accuracy and minimal product wastage. The machine’s hygienic design, with food-grade stainless steel, prevents contamination and meets strict health and safety standards. Suitable for large-scale dairy production, it offers high-speed performance without compromising on quality. Easy-to-operate controls and an ergonomic design make it user-friendly and efficient, even under demanding production conditions.

Automatic Servo Liquid Filling Machine The Automatic Servo Liquid Filling Machine is a state-of-the-art system designed for high-speed and high-precision liquid filling. Using servo-driven technology, it delivers exceptional accuracy, reducing waste and ensuring consistency in every fill. This machine can accommodate a wide range of liquid viscosities, from water-like solutions to thick gels, making it versatile for different industries, such as food, pharmaceuticals, and cosmetics. Built for ease of use, it features a user-friendly touchscreen interface and simple calibration settings. Its robust construction and automated operation increase productivity while minimizing downtime.

Ploughshare Mixer The Ploughshare Mixer is designed for intensive mixing of dry powders, granules, and pastes, making it highly effective in the pharmaceutical, food, and chemical industries. It uses plough-shaped mixing elements that rotate at high speed, ensuring thorough blending and achieving uniform product consistency. This mixer can handle both delicate and heavy-duty applications, making it versatile for a wide range of materials. Built with stainless steel construction, it meets high hygiene standards and is easy to clean, minimizing cross-contamination risks. The mixer also offers customizable options for temperature control and additional features like liquid injection for added functionality.

Vacuum Transfer System The Vacuum Transfer System is a powerful and efficient solution for the safe and contamination-free transfer of powders and granules in pharmaceutical and food manufacturing. It uses vacuum pressure to move materials through a sealed pipeline, preventing exposure to external contaminants and minimizing product loss. The system is ideal for transferring materials between different production stages, such as mixing, drying, or packaging. Its robust design ensures minimal maintenance while maximizing throughput, making it a reliable component for continuous operation. The vacuum transfer also minimizes dust generation, promoting a cleaner and safer working environment.

This article explores a wide array of industrial manufacturing machines, highlighting their unique features, capabilities, and applications across various sectors. It starts with the Fluid Bed Dryer, known for its efficient and uniform drying of powders and granules, followed by the Fluid Bed Processor, which offers versatile processing for drying, granulating, and coating. Machines like the Ointment Manufacturing Plant and Liquid Filling Machine are tailored for pharmaceutical and cosmetic production, ensuring high precision and consistency. The V Blenders and V-Type Blenders provide effective mixing solutions for powders, while the ROPP Capping Machine and Screw Capping Machine ensure secure and reliable sealing for bottles.

youtube

0 notes